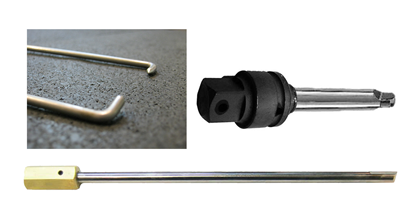

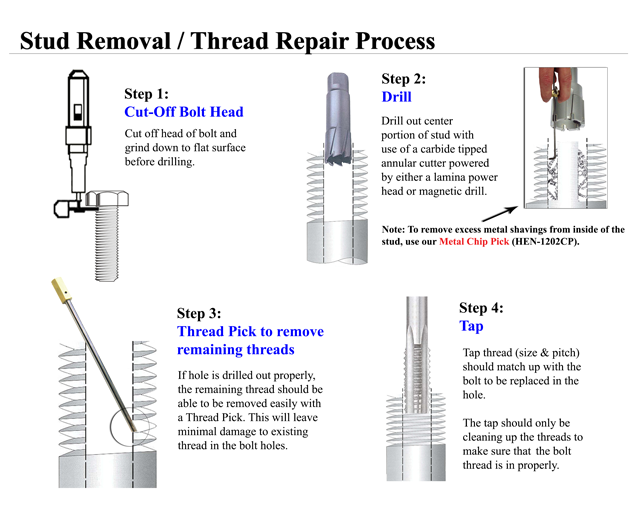

Stud Removal 1"-8

13/16" Diameter Carbide Tipped Annular Cutter

13/16" Diameter Carbide Tipped Annular Cutters in 1", 2", 3", 4", 6", and 8" depth of cut with 3/4" weldon shank. Our 3/4" diameter carbide tipped annular cutters produce holes 3x faster than twist drills and leave clean, burr-free holes. Flutes run the length of the cutter for efficient chip clearance, less chatter, decreased cutter breakage, and increased drilling productivity without pre-drilling or step-drilling.

Our 13/16" diameter carbide tipped annular cutters produce holes 3x faster than twist drills and leave clean, burr-free holes. Flutes run the length of the cutter for efficient chip clearance, less chatter, decreased cutter breakage, and increased drilling productivity without pre-drilling or step-drilling.

Our 13/16" diameter carbide tipped annular cutters produce holes 3x faster than twist drills and leave clean, burr-free holes. Flutes run the length of the cutter for efficient chip clearance, less chatter, decreased cutter breakage, and increased drilling productivity without pre-drilling or step-drilling.

Benefits of H.D. Chasen's 13/16" Diameter Carbide Tipped Annular Cutters

- - More accurate holes with increased cutting speed.

- - Minimized tooth load and tool wear for long life.

- - Tapered inner wall for smooth, easy slug ejection.

- - Center pilot pin for internal lubrication and slug removal.

- - Able to resist higher temperatures, TCT cutters glide through the toughest of materials.

- - Ideal for tough alloys and hardened steels, perfect for bridge repair, truck chassis, steel erection, and power plant maintenance.

Application for Annular Cutters

| Annular Core Cutter Category | Carbide Tipped Annular Cutters | High Speed Steel Annular Cutters | |

|

Mild Steel | ||

|

Structural Steel | ||

|

Construction Steel | ||

|

High Strength Steel | ||

|

Fine Grain Steel | ||

|

Stainless Steel | ||

|

Aluminium | ||

|

Copper/Brass | ||

|

Cast Iron | ||

|

Plastics |

You Might Also Like

Thread Tap 1-8

1-8 Taps. A tap is a cutting tool used to create internal threads in holes or drilled openings in various materials, including metal, plastic, and wood. The process of creating threads using a tap is called tapping. Taps are essential tools for manufacturing threaded components and for assembling parts with threaded connections.

Configurations for Thread Taps

Taper Tap

A taper tap, also called a starter tap, has a gradual thread profile. Typically taper taps are used to start threads in a hole. They are designed to be used first in a series of tapping operations.

Plug Tap

A plug tap has a slightly shorter chamfer than a taper tap and is used to continue threading after the taper tap has started the threads. It's a versatile choice for many applications. They are extremely popular and are used for through holes and can even be used to start blind holes.

Bottom Tap

A bottom tap, also called a bottoming tap, has a very short chamfer and is used to thread close to the bottom of a blind hole where a through-hole doesn't exist.

.png)