Helical Threaded Inserts are used when alternate methods of repairing a threaded hole are inconvenient, impractical or impossible. The use of helical threaded inserts are much easier than plugging a damaged hole with weld bead, redrilling and tapping. It’s usually more practical than using an oversized bolt. Replacement of the entire damaged part could well be impossible as well as costly and time-consuming.

While helical threaded inserts offer an expedient solution to an immediate problem, their benefits don’t end there. Almost all threaded fasteners contain minor errors in pitch of threaded form which tend to concentrate the load on some threads. The free coils of the helical thread insert can flex to accommodate form and pitch variations, thus distributing the load most efficiently over all threads.

Benefits of H.D. Chasen's Helical Threaded Inserts

-

Durability

The elastic properties of H.D. Chasen's Helical Threaded Inserts distribute load and tension uniformly. Resulting in a higher-quality screw joint compared to a screw joint without helical threaded inserts.

-

Potential for Lightweight Construction

Perfect for lightweight construction, helical threaded inserts combines minimum spatial requirements with high load capacity. You can use high-strength screws optimally in low shear strength materials. Fewer connection points and reduced screw dimensions result in less material, reduced install space and lower weight.

-

Wear Resistance

Helical threaded inserts are abrasion-resistant. The high surface quality of the rolled internal thread made of 304 stainless steel ensures a high-strength thread. Moreover, this thread has a constant, extremely low thread friction torque.

-

Thread Friction

Helical threaded inserts reduce thread fiction and its scatter range. This means that for a torque-controlled screw tightening application, the screw preload force can be adjusted more precisely, i.e. the yield point of the screw is utilized more efficiently.

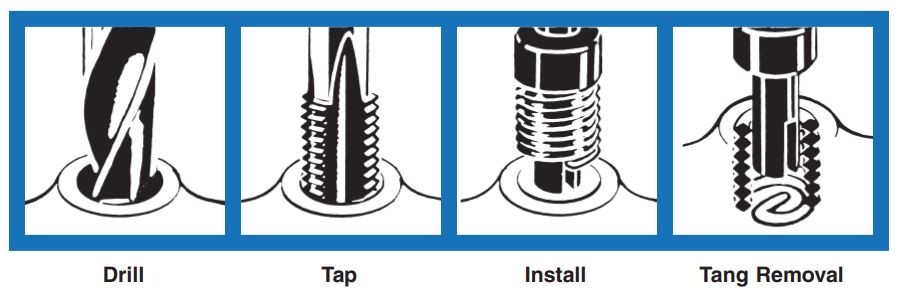

Simple Installation Process

The first step in creating a new, stronger thread is cleaning up the original, damaged threads. This is done with a standard drill, kits do not include drills, please find the reccommended drill size below. The hole is then tapped with an oversize (STI)* tap provided in each thread repair kit. The free diameter of the helical threaded inserts is larger than the new threaded hole, but it is easily “wound” into place with the inserting tool provided.

Once in place, the helical threaded insert tends to spring back to its original diameter, giving it a very strong grip in the hole. Finally, the driving tang is broken off by tapping downward with the end of the inserting tool.

You May Also Like

M2.2 x 0.45 Thread Repair Kit

#42 Jobber Drill Bit

Metric Helical Threaded Inserts

Fractional Inserts

Machine Screw Size Inserts

NPT Inserts

Metric Thread Repair Kits

Fractional Thread Repair Kits

Machine Screw Thread Repair Kits